The Benefits of Polyurethane Packaging for Product Protection

Introduction to Polyurethane Packaging

Polyurethane packaging is a versatile and highly effective solution for protecting products during storage and transportation. While many people associate polyurethane with furniture and bedding, it also plays a crucial role in the packaging industry. Its lightweight, flexible, and resilient nature makes it particularly useful for securing fragile and delicate items.

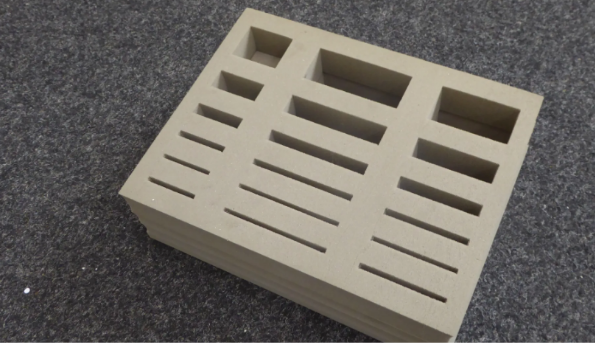

Polyurethane packaging can be customized into various forms, such as foam blocks, shaped inserts, or “egg box” foam, which features peaks and troughs to securely hold products of different shapes and sizes. This type of packaging is widely used across industries, including electronics, jewelry, ceramics, medical equipment, and computer parts distribution.

One of the most popular applications of polyurethane packaging is in polyurethane foam inserts, which provide enhanced protection by cushioning products against shocks and impacts. These inserts can be custom-cut to fit specific components, ensuring that items remain securely in place during transit.

Advantages of Polyurethane Packaging

1. Lightweight and Flexible

Polyurethane packaging is exceptionally lightweight, making it an ideal choice for businesses looking to reduce shipping costs. Despite its low weight, it offers excellent flexibility, allowing it to adapt to the shape of different products without compromising protection.

2. Resilience and Durability

This type of packaging is highly resilient and capable of withstanding repeated impacts without losing its protective properties. Unlike some other packaging materials, polyurethane foam retains its shape and cushioning effect even after multiple uses.

3. Ideal for Fragile Products

Polyurethane packaging is particularly beneficial for delicate items such as electronics, glassware, and medical equipment. Its soft yet sturdy structure helps absorb shocks and vibrations, minimizing the risk of damage.

4. Customizable Design

Polyurethane foam inserts can be precisely tailored to fit specific products, ensuring a snug and secure fit. This level of customization enhances product safety and presentation, making it an excellent choice for premium packaging solutions.

5. Multi-Drop and Dust-Free Applications

Polyurethane packaging is suitable for multi-drop logistics, where products undergo frequent handling and transportation. Additionally, its dust-free nature makes it a preferred option for medical and high-precision equipment.

Polyurethane Foam Inserts for Enhanced Protection

Polyurethane foam inserts offer a superior level of product protection by cushioning items against shocks, vibrations, and sudden movements. These inserts are commonly used in protective cases, industrial packaging, and retail displays.

Key Benefits of Polyurethane Foam Inserts

- Superior Shock Absorption: The foam structure effectively absorbs impact, reducing the risk of product damage.

- Custom Fit: Inserts can be designed to perfectly fit specific products, preventing movement within packaging.

- Versatile Applications: Suitable for various industries, including electronics, automotive, and healthcare.

- Multiple Density Options: Available in different densities and colors to meet diverse packaging needs.

The Complete Packaging Solution

Many packaging suppliers provide a complete service by offering both polyurethane fitments and outer cartons, ensuring that the packaging design is optimized for durability and cost-effectiveness. By sourcing packaging materials from a single supplier, businesses can simplify their order management, streamline paperwork, and maintain balanced stock levels.

Additionally, polyurethane packaging can be complemented with other protective materials such as bubble wrap, adhesive tape, and corrugated boxes, creating a comprehensive packaging solution that meets various industry requirements.

Industries That Benefit from Polyurethane Packaging

Polyurethane packaging is widely used across multiple industries due to its ability to provide reliable protection for delicate and high-value products. Some of the key industries that rely on polyurethane packaging include:

1. Electronics

Sensitive electronic components, such as circuit boards, microchips, and mobile devices, require superior protection from static electricity, moisture, and impact. Polyurethane packaging, especially foam inserts, offers excellent cushioning and prevents damage during transit.

2. Jewelry and Luxury Goods

Jewelry items are often small, delicate, and valuable, making them vulnerable to scratches and breakage. Polyurethane foam inserts provide a soft and secure fit, ensuring that these items remain in pristine condition.

3. Medical Equipment

Medical devices and surgical instruments require precision packaging to prevent contamination and damage. Polyurethane foam is dust-free and can be sterilized, making it an ideal choice for medical packaging solutions.

4. Automotive Industry

Polyurethane packaging is widely used in the automotive sector to protect vehicle components, tools, and spare parts. Its shock-absorbing properties help prevent damage during shipping and storage.

5. Industrial and Manufacturing

Factories and distribution centers use polyurethane packaging for transporting machine components, fragile tools, and precision-engineered products. Custom foam inserts ensure that each component remains secure throughout the supply chain.

Polyurethane packaging is best suited for fragile and lightweight products, whereas polyethylene packaging is ideal for heavy-duty protection and multi-trip applications.

Environmental Considerations and Sustainability

With increasing concerns about environmental sustainability, many businesses are looking for eco-friendly packaging solutions. While polyurethane packaging is not biodegradable, it can be reused and recycled in certain applications. Some suppliers offer sustainable foam alternatives that reduce environmental impact while maintaining high protection standards.

Businesses looking for sustainable solutions can also explore biodegradable foam options or opt for recycled polyurethane materials to minimize waste.

Read Also: Simple Steps to Transition from Spreadsheets to Construction Management Software

Conclusion

Polyurethane packaging is a highly effective and versatile solution for protecting products across various industries. Its lightweight, flexible, and shock-absorbing properties make it ideal for securing fragile and valuable items. With the availability of polyurethane foam inserts, businesses can achieve a customized and reliable packaging solution that enhances product safety and presentation.

For companies looking to optimize their packaging strategy, polyurethane packaging offers a cost-effective and efficient solution that ensures products arrive safely at their destination. By choosing the right packaging materials and working with experienced suppliers, businesses can improve their logistics, reduce damage rates, and enhance customer satisfaction.